Why Turbochargers, Intercoolers and Hi-Flow Exhausts work so well on diesel engines. - Fact Sheet

- locked2go

- Dec 18, 2020

- 4 min read

Updated: Mar 27, 2021

A turbocharger increases engine torque by delivering additional air to sustain efficient combustion at higher fuel flows, which typically occur under load. The turbocharger itself makes no demand for extra energy since it is powered by the heat energy in the exhaust gases which would otherwise be wasted.

The opposite to a supercharger which is belt driven, which use more energy than they deliver at lower RPM.

Rather than being expelled into the atmosphere via the standard exhaust, the super hot (due to the richer, ie hotter exhaust gases that occur at times of extra load: extra fuel) exhaust gases are channelled to drive a turbine wheel in the turbo exhaust housing. It is the rapid expansion of these gases as they cool, that drives the turbine, not high RPM. The Law of Adiabatics – as a gas cools it expands, as the gases move away from combustion they are expanding at the greatest rate as they are cooling at the greatest rate, hence drive the exhaust turbine most strongly.

Think of when the engine RPM remain constant but the accelerator pedal is pushed down. Typical examples are turning into a head wind, going up a long gradient, towing a van or camper, these are the times the amount of fuel being injected is increasing for the same RPM. More fuel, same air, leads to a richer hotter mixture, leads to hotter exhaust gases which expand more quickly than ‘normal’ load exhaust gases, so the exhaust turbine is driven harder.

This in turn drives the compressor wheel at the other end of the turbo shaft. As this compressor wheel spins, it draws clean air from the aircleaner and pushes it into the engine under pressure. This is ‘Boost Pressure’. The maximum Boost Pressure can be adjusted via the wastegate (an internal trap door inside the turbo exhaust housing that allows exhaust gases to bypass the turbine and flow directly into the exhaust pipe), as the trap door opens Boost Pressure levels out.

On modern turbochargers fitted to ECU controlled engines, the pitch of the vanes is altered to control boost pressure. Either by vacuum control or an electric motor called a Stepper Motor, bolted to the side of the turbo.

A turbocharger literally turns waste exhaust gases into energy. While doing so it increases fuel efficiency and reduces exhaust emissions and is the most effective and economical method of making an internal combustion engine more energy efficient.

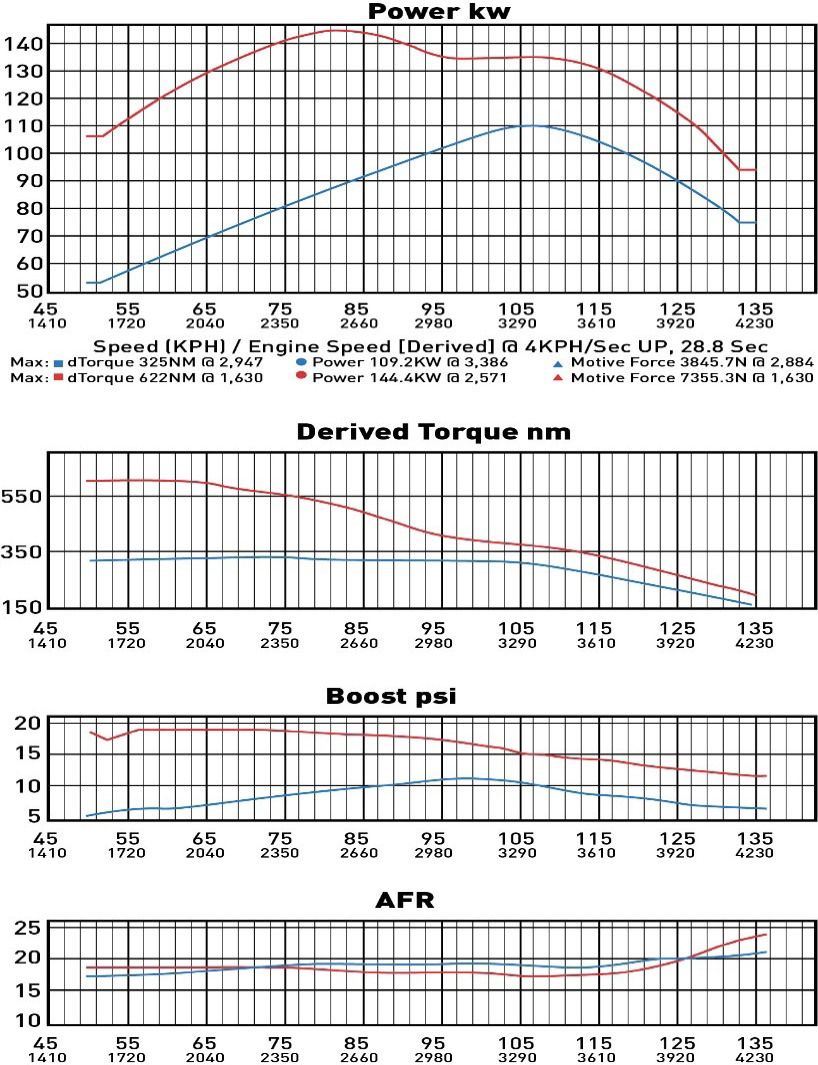

Increasing both turbocharger Boost Pressure and fuel input increases combustion temperature, hence energy output of the engine. Ultimately the maximum output of the engine is limited by combustion temperature and engine component failure.

Combustion temperatures are interpreted from Exhaust Gas Temperatures, EGT’s, with a probe fitted into the dump pipe, or as close to the exhaust manifold as possible. A combination EGT and Boost Gauge makes very good sense, the driver can monitor both readings at all times.

An Intercooler is fitted between the turbocharger outlet and the engine intake manifold, to reduce intake air temperatures. This allows the setting of higher boost and fuel loads but retain moderate combustion temperatures, required for engine longevity.

It’s well established throughout the 4WD community that large capacity, high flow exhausts are of great benefit to the modern 4WD. Increased torque over a wider RPM range result in a more flexible engine with improved economy.

Why does it Work so well in Turbo Diesel:

The Law of Adiabatics – as a gas cools it expands, as the exhaust gases move away from combustion they are expanding at the greatest rate, as they are cooling at the greatest rate. The turbine spins earlier due to the greater space for the hot exhaust gases to expand into.

It’s the expansion of the gases that make the turbo spin, as they rush past the turbine into the greater space provided by the larger exhaust.

The earlier spinning leads to earlier boost pressure which leads to improved efficiency, hence improved economy and lower down torque.

Mandrel bends do not have reduced diameter like factory compression bends, but this is a minor improvement compared with muffler design and the fundamental improvement gained by the increased pipe diameter.

Pre-DPF kits come with a dump pipe, Post-DPF fit onto the rear of the DPF. From there a kit should have a flex joint, hi-flow mandrel bends, mount to the original mounting points with a choice of muffler, straight through pipe or hotdog. They can be as quiet as the factory system or as noisey as a drag car.

Note, more noise does not equate to greater flow.

The reason? Remember, diesel fuel detonates due to the compression of the air-fuel mixture on the compression stroke, and it is the compression that lifts the temperature of the fuel to ignition. If there is not enough ‘back pressure’, the exhaust gas flow out is so fast that upper cylinder temperatures reduce to the point where more compression energy is required to cause combustion. More energy is used from the other ‘firing’ cylinders to force the piston higher (to get compression), hence energy is being absorbed, overall power output is reduced. Timing of the piston position vs fuel delivery is also altered, reducing power output further.

For more low down torque for 4WDing, better towing and safer overtaking on-road, with improved economy, the hi-flow exhaust will make a noticeable difference, up-to 15%.

For more significant gains, investigate ECU Re-mapping.

Summary

Available in Turbo Back and DPF back

Available in a variety of noise levels: straight pipe, hot-dog or hi-flow muffled

409 Stainless with 3” Mandrel Bends

10mm Thick flanges

Fix to OE mounting points

DIY Kit gaskets, high tensile zinc plated nuts, bolts & washers

Manufactured in Australia

3 Year Warranty

_Page_1_edi.png)

Comments