PART 3 - LEARNING TO LOVE YOUR COMMON RAIL DIESEL - Exhaust Gas Recirculation

- locked2go

- Feb 5, 2021

- 4 min read

Updated: Mar 27, 2021

EGR - Exhaust Gas Recirculation

In 2003, EGR valves were introduced to diesel engines in Australia.

In a bid to reduce emissions, burnt exhaust gases are recycled back into the engine, via the inlet manifold and the EGR valve.

This valve is controlled by the ECU, and it opens in circumstances where the ECU determines there is an opportunity to reduce emissions.

Typically emissions are greatest with slow running, short trips, low engine temperatures, excessive idling.

So, in these circumstances, the ECU will try to contain the worst of the emissions by opening the EGR valve, re-burning the smoke and particulates.

However, this is the problem, unburnt fuel and particulates, etc are being fed back into the inlet manifold, and form restrictive deposits.

Compounding Emission Systems Failure

The oil fumes from piston ring blow-by combine with the sooty diesel exhaust gases being fed into the inlet manifold by the EGR valve. The EGR is usually located on the inlet manifold and there are several points that follow:

The thick black paste of particulates mixed with oil build up in the manifold, in the head ports, on the valve stems and valve seals.

The thick black paste bakes into a very hard ‘scale’ the closer it deposits to the engine.

The flow of gases is never evenly spread across all cylinders.

The thick paste from Point 1, the EGR valve can be physically restricted, either ‘gummed’ up and jammed shut, leading to an engine warning engine light.

Alternatively, it can be jammed partly or fully opened.

EGR valves can jam open or shut with the mix of particulates occurring right at the valve.

If jammed open, significant volumes of hot exhaust gases flow into the inlet manifold. The engine will choke until turbo boost pressure is great enough to push the exhaust gases back into the exhaust pipe and it can get some normal air. (usually around 2000rpm).

On Ranger and BT50 it can lead to the plastic inlet manifold melting!

Jammed open or partly open will always lead to reduced performance and reduced fuel economy, hence greater emissions. Imagine the circumstance where an EGR feeds into just 2 cylinders, and with the particulate matter and oil build-up, it slowly restricts airflow into those 2 cylinders. Fig 4 The build-up is unknown to the ECU which monitors the incoming airflow at the air-cleaner. Assuming an even distribution of air to all cylinders, it delivers fuel with an even distribution. The reduced airflow into those 2 cylinders leads to increased combustion temperatures, not due to over-fueling, but due to ‘under airing’.

This can result in piston failure due to excessive temperatures. This is the exact circumstance that occurs with the Nissan ZD30 engine (4 cylinder 3.0Li TDI in the GU Patrol, Navara D22), often referred to as the Nissan ‘hand grenade’ - engine failures are so common. The ZD30 is a standout example of poor design, but take no comfort, I have not observed any manufacturers intake system where the particulate matter and oil buildup is evenly distributed across all cylinders.

Prevention is the ONLY sensible option for longevity. Fit a baffled filtered Catch Can.

EGR maintenance

There are a variety of chemical cleaners that can be released into the intake system, to breakdown the built-up deposits.

LTG 4X4 uses the Wynns EGR4, a workshop grade cleaner that is applied directly to the manifold surface, not just a simple ‘spray in the air-cleaner’ gimmick.

A chemical clean cost is typically $150 to $200.

If the buildup is significant or of some age, it may be necessary to remove the inlet manifold and duct work to physically remove the deposits. Sometimes the ‘scale’ deposits have to be chiseled off, they are that hard. We have not seen any chemical cleaner that will successfully remove the hard ‘scale’ deposits found closer to the engine.

This can be time consuming and costs of around $800 to $1200 would not be unexpected.

Clearly prevention is the best option.

EGR ALTERNATIVES

Other alternatives are the fitting of EGR blocking or limiting plates. (Fig5)

These are a stainless steel plate that physically fits between the EGR valve and the manifold. The complete block is suitable for earlier systems, but later engines have EGR flow sensors, which fault when no exhaust gas flow is detected through the EGR.

These are a simple fix, costing under $20 and take an hour or so to fit. Ask LTG 4x4 for a specific price for your application. EGR plates come in a variety of shapes and sizes to suit each application.

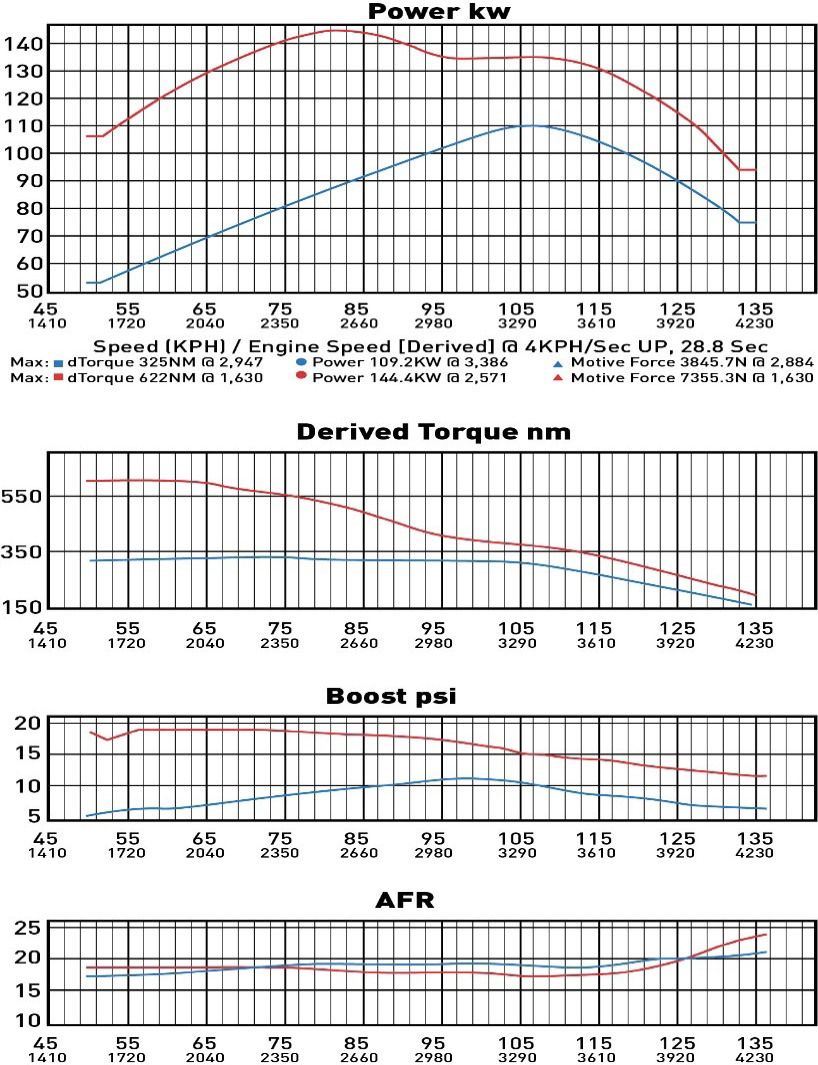

Alternatively, the ECU mapping can be altered so that the EGR valve remains closed at all times. This is usually done in conjunction with a Performance Re-Map, the cost is typically from $1000 to $1600, depending on make, model, year, etc. (see performance enhancement section for more detail)

Any alteration of the emission system may not comply with emission standards for on-road use.

Note: The EGR valve will not open when the turbo is boosting. If it did, turbo boost pressure would be lost down the exhaust pipe, bypassing the combustion chamber. This results in fuel not being combusted due to the lack of air. Vehicles driven harder and for longer tend to have fewer EGR issues.

Thank you for reading the third installment of "Learning to love your common rail diesel" for the next installment about DPF - Diesel Particulate Filter please visit www.ltg4x4.com.au/blog

Cheers,

Tom from LTG 4x4

_Page_1_edi.png)

Comments